Issue

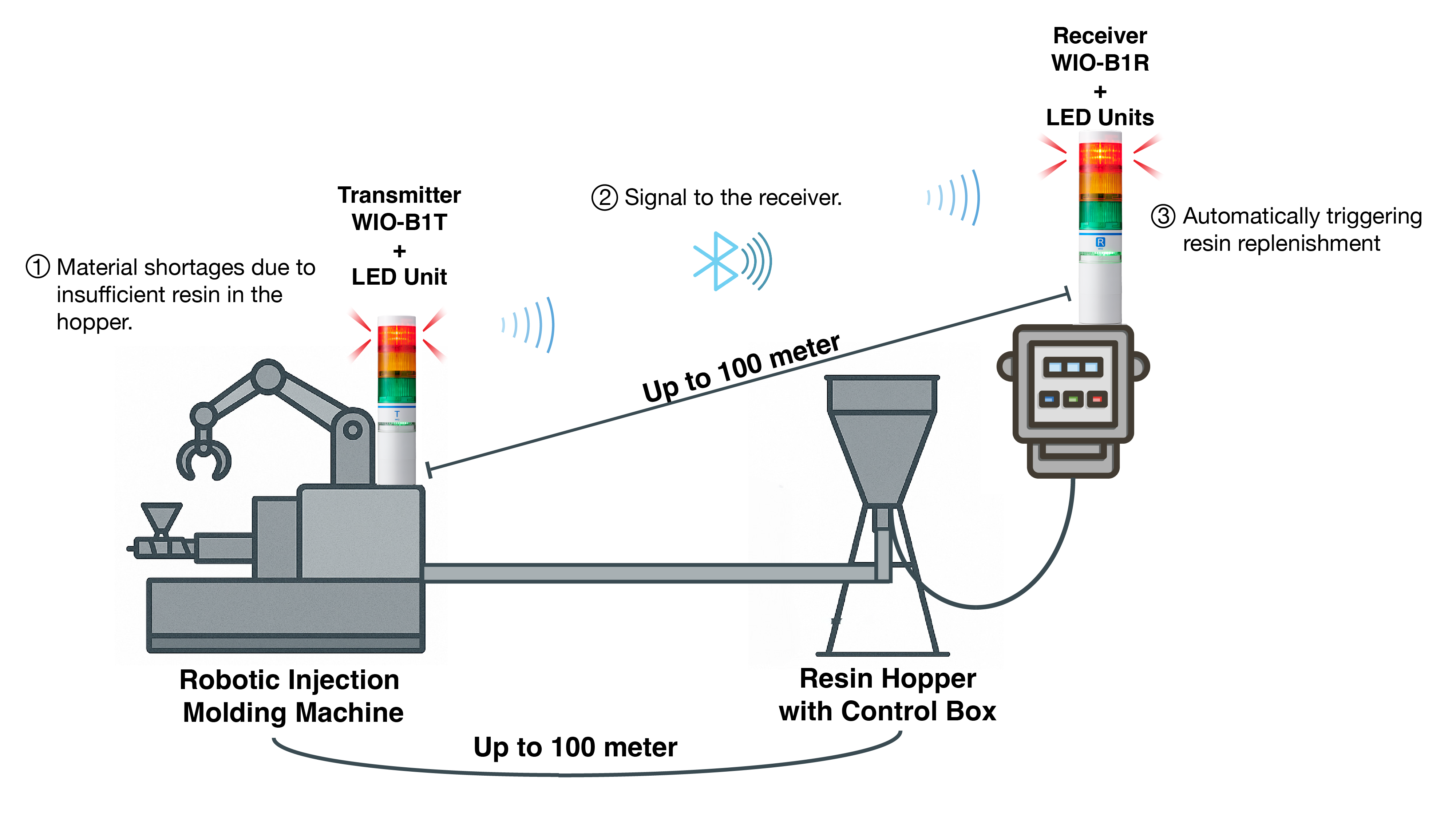

Injection molding machines often face material shortages due to insufficient resin in the hopper. This can cause incomplete mold filling (short shots), production downtime, and material waste. Once the machine stops, it requires multiple scrap shots during restart to stabilize the process, resulting in significant time and material loss.

Solution

By integrating PATLITE's WIO Wireless Control System, the transmitter (WIO-B1T) installed on the injection molding machine remotely signals the receiver (WIO-B1R) at the resin hopper location. When material runs low, the system sends a wireless alert up to 100 meters away, automatically triggering resin replenishment. This remote notification and control setup minimizes downtime, reduces scrap, and ensures consistent production quality.